PRESS BRAKES for

Precision Metal Forming

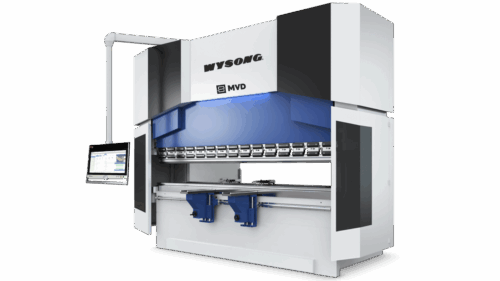

Wysong PRESS BRAKES

Industry-Leading Press Brake Machines

Wysong offers a complete lineup of CNC press brakes designed to meet the diverse needs of today’s metal fabrication industry. With over 20,000 machines still in production worldwide, our press brake machines deliver proven performance for precision metal forming applications. Whether you need the raw power of hydraulic (150-1100 tons), the energy efficiency of electric models, or the versatility of hybrid systems, Wysong has the perfect metal bending solution for your shop.

Our press brakes feature:

- Tonnage range: 150 to 1100 tons

- Bending lengths: 8 Ft to 30 Ft

- CNC control systems for precise, repeatable bends

- Made in USA at our 110,000 sq ft facility in North Carolina

Press Brake Specifications & Capabilities

Choose from our comprehensive range of industrial press brakes engineered for maximum productivity and precision:

Tonnage Capacity

- Light-duty: 150-250 tons for thin sheet metal

- Medium-duty: 250-500 tons for general fabrication

- Heavy-duty: 500-1100 tons for thick plate bending

Key Features

- Advanced CNC Controls: User-friendly programming with 2D/3D visualization

- Precision Back Gauges: Multi-axis positioning for complex parts

- Safety Systems: Light curtains and emergency stops standard

- Energy Efficiency: Up to 50% energy savings with electric and hybrid models

Our Press Brake Lineup

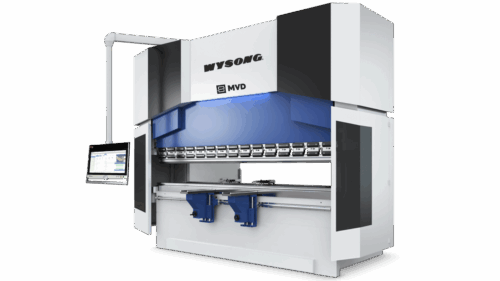

Hydraulic Press Brakes - Power & Reliability

Trusted for decades, Wysong hydraulic press brakes deliver powerful, consistent forming performance. Engineered with rugged steel frames and high-capacity hydraulic systems, these machines handle heavy materials and long bends with ease. Our hydraulic models are ideal for shops requiring maximum tonnage capacity and proven reliability in demanding production environments.

Key Advantages:

High tonnage capacity (up to 1100 tons)

Excellent for thick-gauge materials (up to 6″ thick)

Durable and reliable in tough production environments

Flexible configuration options

Lower initial investment compared to electric models

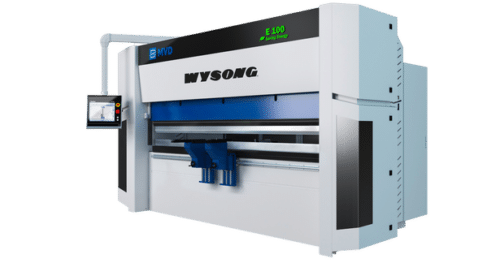

Electric Press Brakes - Precision & Efficiency

Wysong electric press brakes offer high-speed, high-precision forming with lower operating costs. These machines use servo-electric drives for ultra-accurate control and faster cycle times, ideal for thin materials and high-volume production. Experience up to 50% energy savings compared to traditional hydraulic systems.

Key Advantages:

- Reduced energy consumption (50% less than hydraulic)

- Clean, quiet, and eco-friendly

- Minimal maintenance requirements

- Outstanding accuracy and repeatability (0.0004″ precision)

- Faster cycle times for increased productivity

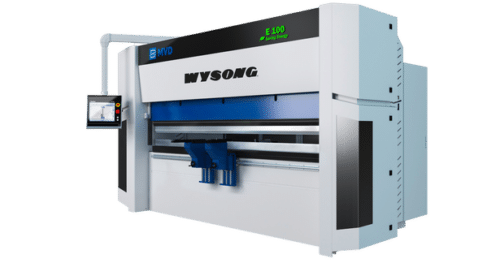

Hybrid Press Brakes - Best of Both Worlds

Combining the best of hydraulic and electric technologies, Wysong hybrid press brakes deliver speed, efficiency, and power. These machines use an electric-hydraulic drive system that improves energy efficiency without compromising tonnage. Perfect for shops transitioning to greener technology while maintaining heavy-duty capabilities.

Key Advantages:

High efficiency and lower energy usage

Quiet operation with less hydraulic fluid

Faster response and cycle times

Excellent bending accuracy

- Reduced environmental impact

Press Brake Applications & Industries

Wysong press brakes serve critical metal forming needs across diverse industries:

Industries We Serve:

- Automotive Manufacturing: Chassis components, brackets, and structural parts

- HVAC & Ductwork: Precision bending for air handling systems

- Construction & Architecture: Structural steel and architectural metalwork

- Agricultural Equipment: Heavy-duty components and implements

- Energy & Power Generation: Electrical enclosures and infrastructure components

- General Job Shops: Versatile solutions for custom fabrication

Common Applications:

- Box and pan forming

- Channel and angle bending

- Complex multi-bend parts

- Large radius forming

- Hemming and seaming operations

Why Choose Wysong Press Brakes?

American Manufacturing Excellence

Every Wysong press brake represents over 70 years of American manufacturing expertise. Built in our 110,000 square foot facility in North Carolina, our machines undergo 40 hours of rigorous quality assurance testing before shipment.

Proven Performance

- 20,000+ machines still in operation worldwide

- Hundreds of years of combined team experience

- Industry-leading warranty and support

- Local service network across North America

Total Cost of Ownership

While the initial investment in a quality press brake is significant, Wysong machines deliver exceptional ROI through:

- Lower energy consumption

- Reduced maintenance costs

- Longer service life

- Higher resale value

- Minimal downtime

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards. This commitment to quality is why over 20,000 Wysong press brakes continue operating in shops worldwide.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Press Brake Buying Guide

Selecting the Right Press Brake

Choosing the right press brake requires careful consideration of:

- Material Requirements

- Types of metal (steel, aluminum, stainless)

- Material thickness range

- Required bend lengths

- Production Volume

- Parts per day/shift

- Batch sizes

- Setup frequency

- Precision Needs

- Tolerance requirements

- Repeatability standards

- Quality control demands

- Shop Environment

- Available floor space

- Power requirements

- Operator skill level

Get Expert Guidance

Our experienced sales engineers will help you specify the perfect press brake for your application. We offer:

- Free consultation and needs assessment

- Tonnage calculations and recommendations

- ROI analysis and financing options

- Training and installation support

Frequently Asked Questions

Tonnage requirements depend on material type, thickness, and bend length. As a general rule, mild steel requires approximately 1 ton per foot of length per millimeter of thickness. Our engineers can calculate exact requirements for your application.

Hydraulic press brakes offer maximum power and lower initial cost, ideal for heavy-duty applications. Electric press brakes provide superior energy efficiency, precision, and lower operating costs, perfect for high-volume precision work.

With proper maintenance, Wysong press brakes typically operate for 20-30+ years. We have machines from the 1970s still in daily production use.

Yes, we provide comprehensive operator and maintenance training both on-site and at our facility. CNC programming support is also available.

Considering a New Press Brake?

Whether you’re forming light sheet metal or heavy structural parts, Wysong has the perfect press brake to power your production. Contact us today to learn more.

- (800) 299-7664

"*" indicates required fields