cnc folders

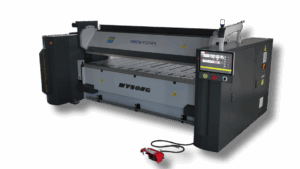

WYSONG Apexfold CNC FOLDERS

Heavy Duty Precision - up to 9 ga capacity

Wysong CNC folders are designed for fabricators seeking to automate their production with precision, speed, and user-friendly operation. Engineered for efficiency, our equipment features advanced CNC controls that simplify programming, minimize setup time, and reduce the need for frequent tool changes—making them ideal for a wide range of materials and thicknesses.

With automated bending capabilities up to 145 degrees, integrated material clamping, and robust support systems, Wysong folders help shops boost productivity without compromising quality.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Sectors Used

PANELS AND

CABINETS

HEATING – COOLING –

VENTILATION SYSTEMS (HVAC)

ELEVATOR AND

ESCALATOR SYSTEMS

MACHINERY COVERS –

COVERINGS

OVERVIEW

Standard Features

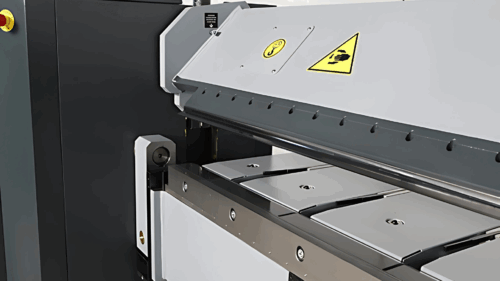

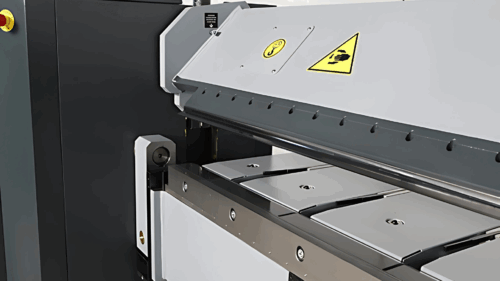

Servo driven clamping and back gauge ( Z and X axis)

High torque AC motorized folding and beam rotation ( Y and C axis)

Ball screw spindle system with dual motor drives on clamping and folding

15.6’’ ESA touchscreen controller on swivel arm

7″ Clamping beam opening height (without tools)

5″ high goat foot tools on station 1

30° – R1 sharp nose clamping beam tools on station 2

Folding beam tools as 10 or 15 or 25 and 35 mm (2 sets)

Manual folding beam adjustment 35 mm (A axis)

30″ rectangular back gauge table with ball casters

Front light barriers

3 switch foot pedal

Optional Features

1500 mm or 1000 mm servo backgauge system with rectangular sheet support table.

2500 / 3200 / 4200 mm servo backgauge system upgrade with L / U shape sheet support table options.

2D/3D CNC Graphic Control Software.

Manual crowning system.

Servo folding beam adjustment.

Omega geometry upgrade on lower and folding beam.

Manual conical backgauge finger.

Motorized conical backgauge system.

Pneumatic goat foot tool quick clamping system.

Apexfold Series

Apexfold 2050

Folding Length

80" // 2050 mm

Mild Steel

6 ga // 5 mm

Stainless

13 ga // 2.5 mm

Aluminum

1/4" // 7 mm

Apexfold 2545

Folding Length

100" // 2550 mm

Mild Steel

7 ga // 4.5 mm

Stainless

13 ga // 2.5 mm

Aluminum

.236" // 6 mm

Apexfold 3240

Folding Length

126" // 3200 mm

Mild Steel

9 ga // 4 mm

Stainless

15 ga // 2 mm

Aluminum

6 ga // 5 mm

Apexfold 4230

Folding Length

165" // 4200 mm

Mild Steel

11 ga // 3 mm

Stainless

17 ga // 1.5 mm

Aluminum

9 ga // 4 mm

options

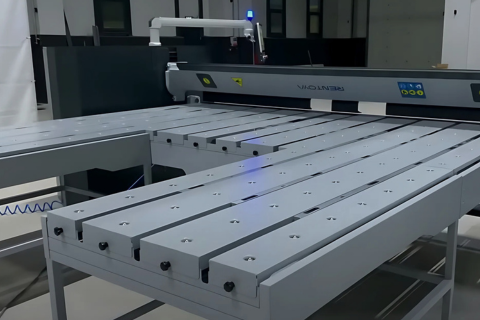

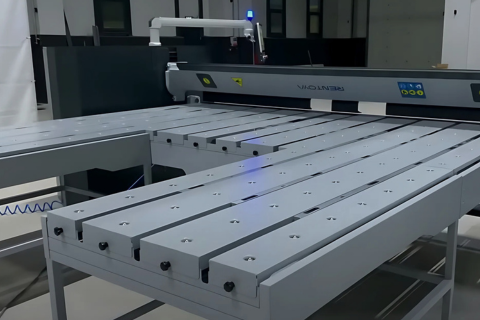

Rear Table Design

While the folding beam performs the actual bend, the table shape determines how the operator or automation system interacts with the material. Choosing the right table layout depends on your part sizes, bend sequences, and overall workflow.

Rectangular tables are the most common configuration and are well-suited for standard sheet sizes and general-purpose bending.

U-shaped tables provide enhanced support for long or wide parts and are designed to keep material centered around the folding beam. This configuration is particularly useful when forming large panels, such as those used in architectural cladding, HVAC ducting, or enclosure fabrication.

L-shaped tables are designed for flexibility in handling irregularly shaped or asymmetrical parts. This layout provides extended support on one side, which can be especially helpful when forming boxes, cabinets, or parts with off-center features.

Upper Beam options

The upper beam on a CNC folder is responsible for clamping the material during the bending process and plays a key role in the machine’s flexibility, accuracy, and tooling versatility.

Stationary upper beams are simple, robust, and highly repeatable, making them ideal for high-volume, low-variation production environments. Because the tooling does not rotate, setup and operation are straightforward, and there’s less risk of mechanical misalignment over time. However, stationary beams are limited in their ability to accommodate complex part geometries or return bends that require clearance for formed flanges.

Rotary upper beams feature a clamping head that can rotate between two different tooling profiles, allowing the machine to switch between tools without manual changeover. Rotary beams are ideal for high-mix production and parts that include return flanges or deep box profiles, as they provide the necessary clearance without interrupting the bending cycle.

Upper Beam Height

The height of the upper beam on a CNC folder significantly influences the machine’s ability to form deep parts, handle complex bend sequences, and reduce interference between previously bent flanges and the tooling.

Standard-height upper beams are typically sufficient for flat parts or those with minimal vertical features. For simple U-channels, shallow boxes, and single-flange bends, a standard beam height provides ample clearance while maintaining rigidity and accuracy.

Extended-height upper beams, often referred to as high-opening or high-lift beams, are designed to accommodate taller part geometries and more complex forms. With increased vertical travel, the upper beam can raise higher above the work surface, allowing operators to manipulate deep boxes or multi-sided parts without interference. This feature is especially beneficial when working with large electrical enclosures, HVAC ducting, and architectural panels that require multiple bends in close succession. High-opening beams also simplify part rotation during the bend sequence, reducing the chance of collisions.

Improve Your Workflow with

CNC Folding Machines

Designed to outperform traditional press brakes in specific applications, cnc folders excel at complex bends, large panels, and short flanges, while delivering repeatable accuracy and dramatically reducing operator fatigue. Whether you’re forming light-gauge aluminum or thick stainless, Wysong cnc folders like the Apexfold series make setup fast, operation simple, and production consistent.

Why Use CNC Folders?

Improves Accuracy – Automated folding delivers exact bend angles and dimensions with repeatable precision

Handles Complex Parts Easily – Produce box shapes, tight hems, and return bends without repositioning

Speeds Up Production – Rapid setup and automatic bending sequences reduce cycle time and boost throughput

Eliminates Double Handling – Complex bend sequences can be programmed into a single operation with no flipping or rotating

Improves Ergonomics – Operators don’t need to support or manipulate heavy sheet metal during forming

Simplifies Tooling – One set of folding tools replaces multiple press brake punches and dies

Ready to Kick Start Your Production?

Discover how Wysong CNC folders can boost your productivity and precision.

- (800) 299-7664

"*" indicates required fields