High-Speed Shears

Wysong High-Speed Mechanical Shears

Engineered to Perform.

Engineered to Perform.

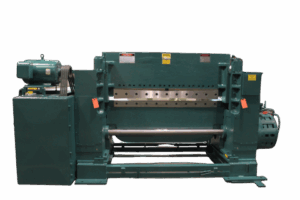

Our high-speed metal shearing machines are meticulously designed to deliver precision and efficiency, making them ideal for fast-paced metal fabrication tasks. Perfect for companies that require rapid processing, these high-speed sheet metal shears provide reliable performance, ensuring that your production stays on schedule without compromising on quality. Equipped with advanced technology, our high-speed mechanical shearing machines guarantee accurate and swift cuts, streamlining your production process and enhancing overall productivity. Whether you’re handling large volumes or intricate projects, these machines offer the speed and precision needed to excel in today’s competitive manufacturing landscape.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

OVERVIEW

High Speed Mechanical Shears

Key Features & Advantages:

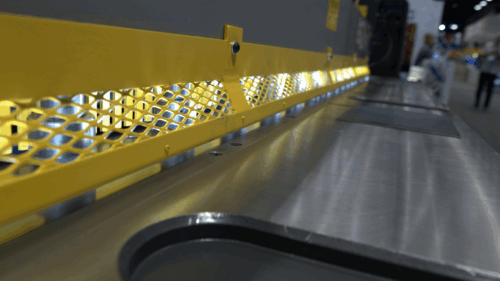

High-Speed Cutting: Wysong shears are optimized for speed, making them ideal for high-volume environments. Rapid blade cycles with up to 300 strokes per minute reduce production time while maintaining accuracy and edge quality.

Heavy-Duty Construction: Cast Iron frames and high-quality components ensure long-term durability, even under continuous use. Wysong mechanical shears are built to handle demanding applications with minimal maintenance.

Custom Configurations: Available in a variety of sizes and capacities to match your material and throughput requirements.

options

Strokes per Minute (SPM)

Wysong shears are engineered for speed, precision, and versatility; delivering performance that meets the demands of a wide range of metal fabrication environments.

For heavier applications cutting steel plate, our heavy duty shears rated at 60 strokes per minute provide the power and stability needed for clean, accurate cuts, without sacrificing safety or material integrity. Ideal for job shops, manufacturers, and service centers handling thicker materials or larger part sizes.

When higher throughput is essential, such as in HVAC, appliance, or light gauge fabrication our high-speed shears can offer either 200 or 300 strokes per minute to deliver fast, consistent performance without compromising cut quality. These shears excel in medium- to high-volume operations, where keeping up with production schedules is crucial.

Drivetrain

The choice of drivetrain affects everything from power delivery and responsiveness to maintenance requirements and energy efficiency. Wysong gives fabricators the flexibility to choose a shear that perfectly aligns with their production goals, material types, and operating environment.

Our gearbox-driven shear is the workhorse of the industry, known for its durability and torque. This drivetrain uses a robust motor and gearbox combination to deliver consistent cutting power, especially beneficial when working with thick or high-tensile materials.

Direct drive systems, by contrast, eliminate the need for intermediate gearing by connecting the motor directly to the cutting mechanism. This results in greater energy efficiency, reduced mechanical complexity, and faster response times. Ideal for high-speed, high-volume operations.

Drivetrain

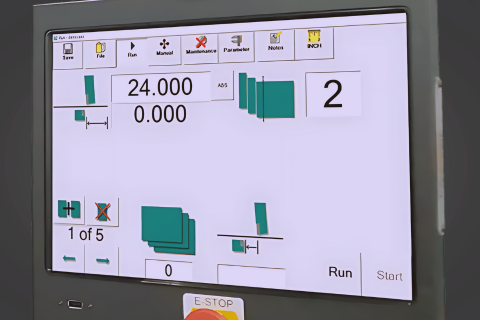

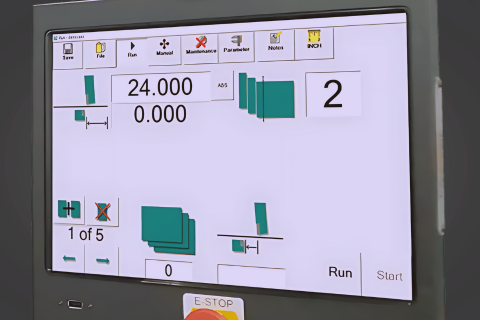

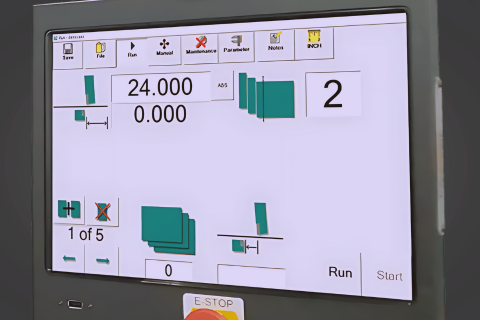

Wysong offers a range of shear control options to suit every production need, from intuitive cnc touchscreen controls to fully integrated cut to length systems. Whether you’re looking for advanced programmability, real-time feedback, or seamless line integration, Wysong’s control options give you the flexibility to operate your shear exactly how your application demands.

We offer multiple touchscreen control options that provide an intuitive platform for programming and operating your Wysong shear. Designed to allow operators to store and recall cut programs, adjust backgauge positions, monitor diagnostics, and manage maintenance alerts, our user-friendly interface makes it ideal for anyone needing rapid setup and repeatable results with minimal training.

In fully automated environments, Wysong cut-to-length line shears are controlled entirely by a central PLC, eliminating the need for operator input at the shear itself. In these systems, cut length, quantity, and sequencing are all determined by the upstream line control, with the shear responding automatically to signals from the master PLC. This integration ensures seamless coordination between feeding, leveling, and cutting processes for coil processing applications.

CNC ControlS

Wysong offers a range of shear control options to suit every production need, from intuitive cnc touchscreen controls to fully integrated cut to length systems. Whether you’re looking for advanced programmability, real-time feedback, or seamless line integration, Wysong’s control options give you the flexibility to operate your shear exactly how your application demands.

We offer multiple touchscreen control options that provide an intuitive platform for programming and operating your Wysong shear. Designed to allow operators to store and recall cut programs, adjust backgauge positions, monitor diagnostics, and manage maintenance alerts, our user-friendly interface makes it ideal for anyone needing rapid setup and repeatable results with minimal training.

In fully automated environments, Wysong cut-to-length line shears are controlled entirely by a central PLC, eliminating the need for operator input at the shear itself. In these systems, cut length, quantity, and sequencing are all determined by the upstream line control, with the shear responding automatically to signals from the master PLC. This integration ensures seamless coordination between feeding, leveling, and cutting processes for coil processing applications.

Improve Your Workflow with

Mechanical Shears

Mechanical shears, such as the Wysong HS Series, are built for speed, reliability, and precision. These machines use a flywheel-driven system to power the blade, enabling consistent and rapid cutting cycles.

Why Use Mechanical Shears?

Advantages of Mechanical Shears:

High-Volume Production: Mechanical shears excel in applications requiring repetitive, high-speed cuts. Their ability to maintain up to 60 strokes per minute (SPM) makes them ideal for industries like automotive, HVAC, and light manufacturing.

Thinner Materials: These machines perform exceptionally well with thinner sheet metals, where precision and speed are critical.

ROI Considerations: For fabricators focused on high-volume, low-to-moderate gauge materials, the speed of mechanical shears can result in significantly higher throughput than a comparible hydraulic shear.

Built in the USA. Supported Nationwide.

Every Wysong high speed shear is proudly designed, manufactured, and assembled in the United States. Our nationwide network of service technicians and parts support ensures your machine keeps running at peak performance.

Ready to Cut Faster?

Let’s cut through complexity—together.

No matter your industry or production scale, Wysong high speed mechanical shears are built to help you process faster and more efficiently.

Get in touch with our experts today to explore the best solution for your operation.

- (800) 299-7664

"*" indicates required fields