Deburring Machines

Deburring Made Simple

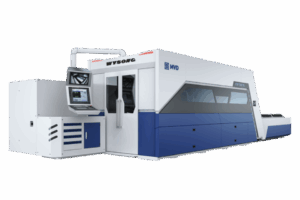

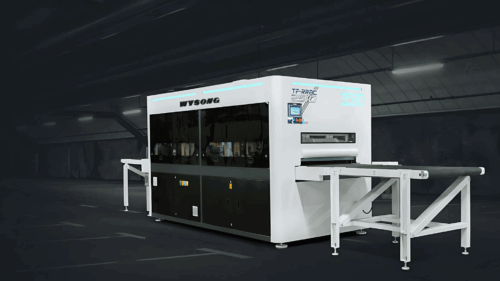

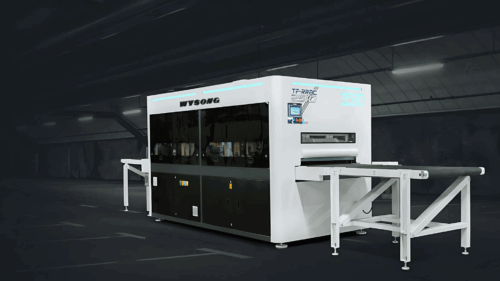

Wysong Surfacer Series deburring machines are designed to take the sharp edges, burrs, and imperfections out of your finished parts, leaving a smooth, consistent surface every time. Built for manufacturers who demand high-quality results, these machines improve safety, part handling, and downstream processes by ensuring each piece is ready for painting, coating, or assembly.

Just like every Wysong product, our deburring machines are backed by a legacy of quality, service, and support. Engineered for versatility, our deburring solutions handle everything from flat sheet metal to more complex shapes, providing uniform edge rounding, oxide removal, and surface finishing in a single pass.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

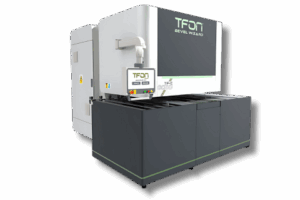

OVERVIEW

Surfacer series

High-Performance Deburring: Consistently removes burrs, sharp edges, and slag for safer, cleaner parts.

Versatile Applications: Processes laser-cut, plasma-cut, punched, or sheared parts in a wide range of materials.

Superior Surface Finish: Achieves smooth, uniform finishes ready for coating, painting, or welding.

Edge Rounding Capability: Rounds and breaks sharp edges for improved part handling and better powder-coat adhesion.

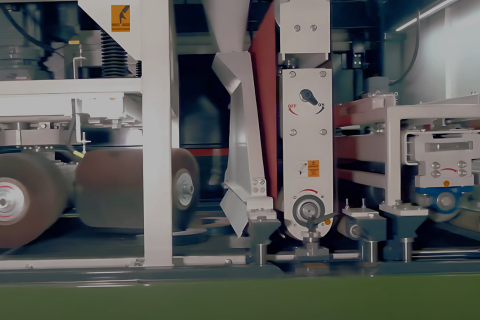

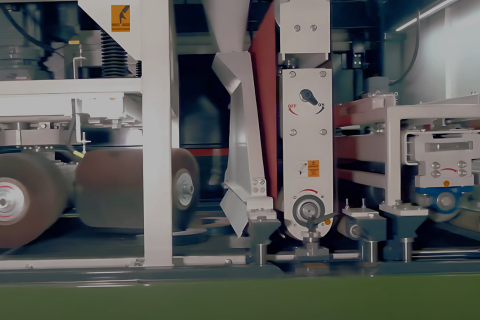

Multi-Station Design: Combines deburring, edge rounding, oxide removal, and finishing in a single pass.

Heavy-Duty Construction: Robust steel frame built for industrial workloads and long service life.

Variable Speed Control: Allows fine-tuning of abrasive belts and brush heads for optimized performance.

User-Friendly Operation: Intuitive controls and easy material loading reduce training time and increase productivity.

options

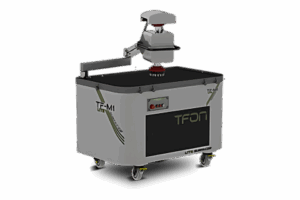

Conveyor System

The optional conveyor system is designed to seamlessly integrate with the Surfacer line, enhancing workflow efficiency and reducing manual part handling. Built with heavy-duty construction and precision alignment, the conveyor ensures smooth and reliable transfer of parts before and after the deburring process for higher volume application.

Whether you’re working with small laser-cut components or large sheet metal parts, the conveyor system streamlines production, minimizes bottlenecks, and supports higher throughput in busy fabrication environments.

Vacuum and Magnetic

Table Systems

Vacuum tables are ideal for non-ferrous materials like aluminum and stainless steel, where traditional magnetic workholding isn’t effective. By creating strong suction beneath the workpiece, the vacuum system prevents movement or lifting during deburring, especially on thin or lightweight sheets. This added stability allows operators to run parts at faster conveyor speeds with greater accuracy and safety.

For ferrous materials such as mild steel, magnetic tables offer powerful holding force that locks parts in place throughout the entire deburring cycle. The magnetic system is especially effective for small, narrow, or irregularly shaped parts that might otherwise shift during belt or brush contact. The result is smoother finishes, sharper edges, and repeatable results—no matter the part size or material.

Vacuum and Magnetic

Table Systems

Vacuum tables are ideal for non-ferrous materials like aluminum and stainless steel, where traditional magnetic workholding isn’t effective. By creating strong suction beneath the workpiece, the vacuum system prevents movement or lifting during deburring, especially on thin or lightweight sheets. This added stability allows operators to run parts at faster conveyor speeds with greater accuracy and safety.

For ferrous materials such as mild steel, magnetic tables offer powerful holding force that locks parts in place throughout the entire deburring cycle. The magnetic system is especially effective for small, narrow, or irregularly shaped parts that might otherwise shift during belt or brush contact. The result is smoother finishes, sharper edges, and repeatable results—no matter the part size or material.

Improve Your Workflow with Automated Deburring Machines

We know every business is different, so we offer a wide range of automated deburring machines to fit any need or budget. Whether you’re looking for a machine that uses water (wet) or one that doesn’t (dry), we have reliable options that are built to last. Our machines reduce maintenance costs and keep your operation running smoothly.

Why Use Deburring Machines?

Better Part Quality: Deburring gives parts a clean, polished look without flaws.

Improved Safety: Smoother edges mean workers are less likely to get cut. Automation also reduces the risk of human error.

Paint Adherence: Removing burrs helps paint or coatings stick properly, preventing peeling or cracking.

Consistent Results: Automated machines produce the same high quality every time, unlike manual work, which can vary.

Time Savings: Machines work faster than manual methods, giving your team more time to focus on other important tasks.

Choose Wysong for Top-Quality Deburring Machines

With Wysong deburring machines, you can be confident your metal parts will look great and perform well. As a trusted manufacturer, we provide reliable, high-performance machines that use advanced abrasive technology to deliver smooth, professional finishes—every time.

- (800) 299-7664

"*" indicates required fields