Finishing Machines

Wysong Finishing machines

Built to Perform. Engineered for Precision.

From high-speed deburring machines to manual edge prep tools and automated leveling solutions, Wysong offers a full range of equipment to match your application. Ideal for laser-cut parts, stamped blanks, and heavy plate work, our finishing machines are built for performance and reliability in demanding environments.

Designed to deliver smooth edges, flat surfaces, and clean profiles, our finishing equipment ensures that every part leaving your shop meets the highest standards for safety, appearance, and functionality. Whether you’re preparing parts for welding, coating, or assembly, Wysong finishing systems help you reduce rework, improve consistency, and save time on downstream processes.

Our Finishing Machine Lineup

Surfacer Series

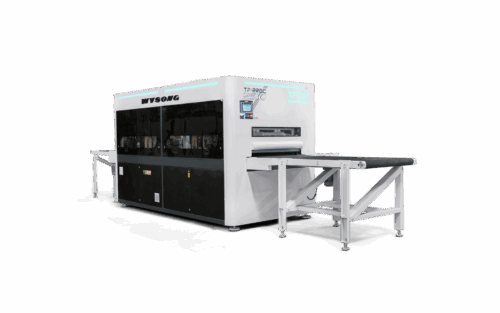

The Wysong Surfacer Series delivers fast, consistent, and high-quality deburring for laser-cut, punched, sheared, or plasma-cut parts. Whether you’re removing sharp edges, slag, or oxide layers, these machines produce clean, safe, and ready-to-finish parts in a single pass. Built for reliability and ease of use, Surfacer deburring machines help shops reduce hand grinding, improve part uniformity, and streamline post-cutting processes.

Key Advantages:

- Available with abrasive belt, brush, or combo head configurations

- Edge rounding, burr removal, and oxide layer removal in one pass

- Variable speed controls for both feed and abrasive heads

- Processes mild steel, stainless steel, aluminum, and non-ferrous metals

- Wide working widths available to accommodate large or small parts

Surfacer Lite Series

The Wysong Surfacer Lite Series offers a cost-effective, compact solution for shops that need efficient, hands-on deburring without the investment or footprint of fully automated systems. Designed for ease of use, these manual deburring machines are ideal for small to mid-sized parts and low-volume production runs. Operators can quickly remove sharp edges, burrs, and slag from laser-cut, punched, or plasma-cut materials with minimal training and setup.

Key Advantages:

Ideal for manual edge deburring, rounding, and surface prep

Compact footprint for small shops and tight workspaces

Simple operation – no CNC or programming required

Compatible with laser-cut, plasma-cut, and punched parts

Non-slip work surface and adjustable tooling for control and safety

Reduces risk of injury from manual grinding or hand tools

Durable construction for daily shop use

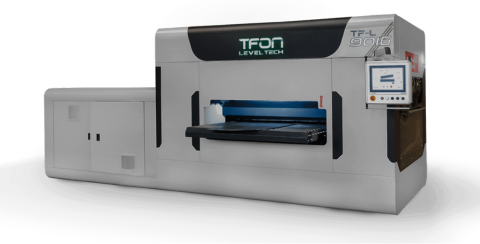

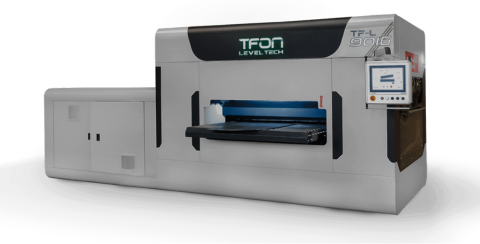

The Wysong Level Tech Series leveling machines are engineered to deliver perfectly flat, stress-relieved sheet metal parts—essential for laser cutting, welding, bending, and assembly. Whether you’re working with laser-cut blanks, stamped parts, or plasma-cut plates, the Level Tech Series eliminates internal stresses and surface irregularities that can lead to bending defects, misalignment, or poor fit-up.

With servo-controlled leveling rollers, adjustable pressure settings, and automated material handling options, Level Tech machines provide powerful, repeatable flattening across a wide range of materials and thicknesses.

Key Advantages:

Precision leveling for laser-cut, stamped, or sheared sheet metal parts

Eliminates internal stresses and part distortion

Handles a wide range of materials

Available in multiple widths and thickness capacities

Reduces rework, scrap, and downstream setup time

Compatible with automated loading/unloading systems

Touchscreen controls for easy setup and repeatable results

Bevel Wizard Series

The Wysong Bevel Wizard Series delivers high-performance edge preparation for weld-ready parts with speed, precision, and ease. Designed to handle a wide range of materials and bevel profiles, these machines are ideal for fabricators who need clean, consistent bevels on plate and sheet metal. Whether you’re working on straight edges or curved contours, the Bevel Wizard makes it easy to produce high-quality bevels that reduce weld time and improve fit-up.

Key Advantages:

Creates precise bevels for weld prep on plate and sheet metal

Adjustable bevel angles and depth settings for custom applications

Reduces manual grinding and improves edge consistency

Suitable for MIG, TIG, and stick welding preparation

Easy-to-use controls with repeatable accuracy

Compact, rugged design built for industrial environments

About Us

QUALITY FIRST

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Ready to Upgrade Your Shop?

Let’s cut through complexity—together.

No matter your industry or production scale, Wysong finishing machines are built to help you process smarter, faster, and cleaner. Get in touch with our experts today to explore the best solution for your operation.

- (800) 299-7664

"*" indicates required fields