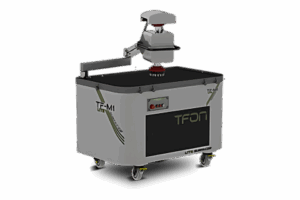

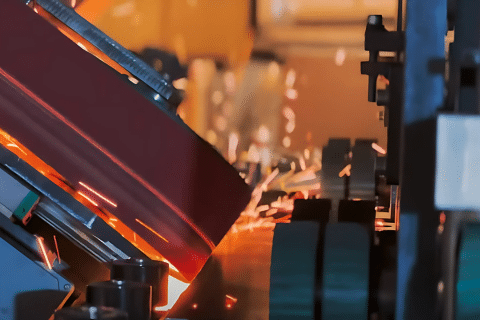

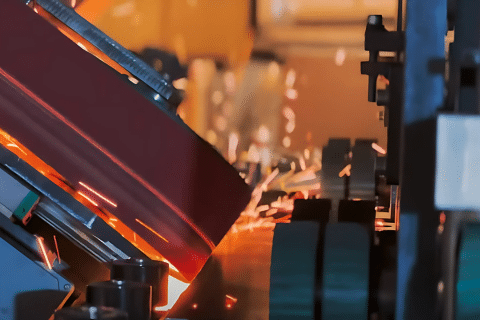

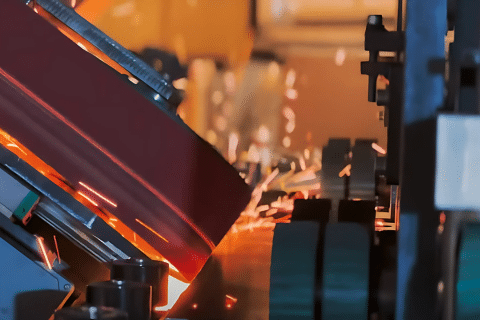

Beveling Machines

weld prep Simplified

Wysong beveling machines are engineered to give fabricators clean, accurate bevels for welding preparation, edge finishing, and part fit-up. Designed to handle a wide range of materials and thicknesses, these machines deliver consistent angles with minimal effort, reducing the time and labor traditionally required for manual grinding.

Unlike manual torch beveling or handheld grinding methods, the Bevel Wizard ensures repeatability, safety, and surface consistency from the first cut to the last, even on non linear parts.

About Us

Quality First

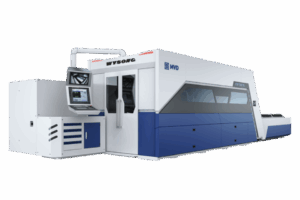

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

OVERVIEW

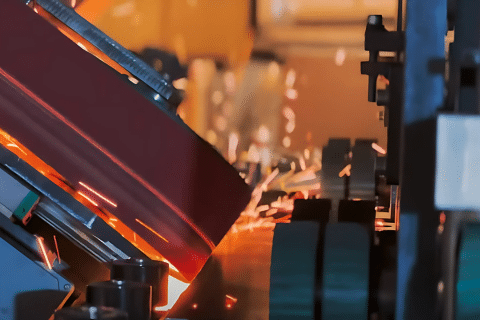

Weld Strong.

Poor edge preparation leads to poor welds. Inconsistent bevel angles, rough surfaces, and hand-ground chamfers can cause incomplete fusion, misalignment, and weld defects that compromise the strength of your final product. Our beveling machines take the guesswork out of edge prep—delivering clean, consistent bevels every time.

Whether you’re working with mild steel, stainless, or aluminum, precise bevels improve weld penetration, reduce rework, and eliminate the need for time-consuming manual grinding. Automated beveling ensures every part is ready for assembly or welding without surprises—faster, safer, and with far fewer defects. Get stronger welds, better fit-up, and cleaner finishes with less operator effort.

Suitable for a Wide Range of Industries

Heavy Equipment Manufacturing – Prepare thick plate weld joints with precise bevels for maximum strength and durability.

Shipbuilding and Marine – Bevel large structural components to meet demanding weld penetration and inspection standards.

Pipeline and Oil & Gas – Create uniform weld preps that ensure high-pressure pipeline integrity in the harshest environments.

Structural Steel Fabrication – Speed up edge prep on beams, columns, and girders for efficient welding and field assembly.

Pressure Vessel Production – Achieve clean, code-compliant bevels that reduce the risk of cracking and porosity in critical welds.

Metal Tank and Silo Fabrication – Cut accurate bevels for circular seams and shell segments, ensuring leak-free assembly.

Aerospace Fabrication – Produce lightweight, high-strength welds on precision parts with consistent bevel geometry.

Railcar and Transit Manufacturing – Improve weld prep on large-scale components to maintain quality and production speed.

Energy and Power Generation – Bevel turbine housings, boilers, and structural frames for stable welds under thermal stress.

General Fabrication – Replace slow, inconsistent grinding with fast, accurate beveling for shops of all sizes.

Improve Your Workflow with

Automated Beveling Machines

One of the most compelling reasons to use a beveling machine is the improvement in weld quality. Proper bevels allow for better weld penetration, which is essential for strength and durability, especially in load-bearing or high-stress applications. Beveled edges create more space for the weld pool, reducing the likelihood of incomplete fusion or porosity. This is particularly important in industries such as shipbuilding, construction, oil and gas, and heavy equipment manufacturing, where joint failure can have serious consequences.

Why Use Beveling Machines?

Improves Weld Penetration – Creates beveled edges that allow for deeper, stronger welds.

Enhances Joint Strength – Beveled surfaces produce cleaner, more structurally sound welds.

Increases Weld Fit-Up Accuracy – Provides consistent, accurate angles for perfect part alignment.

Reduces Weld Defects – Helps prevent issues like lack of fusion, porosity, and cracking.

Speeds Up Edge Preparation – Automates a time-consuming task compared to grinding or torch cutting.

Minimizes Rework – Precise edge prep reduces weld failures and costly do-overs.

Reduces Consumable Use – More efficient cutting reduces the wear on grinding discs and torches.

Choose Wysong for Top-Quality Beveling Machines

With Wysong beveling machines, you can be confident your metal parts will look great and perform well. As a trusted manufacturer, we provide reliable, high-performance machines that use advanced beveling technology to deliver smooth, professional finishes—every time.

- (800) 299-7664

"*" indicates required fields