Compact Fiber Lasers

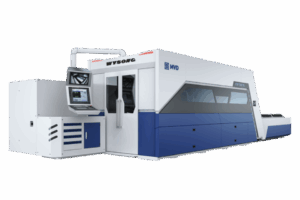

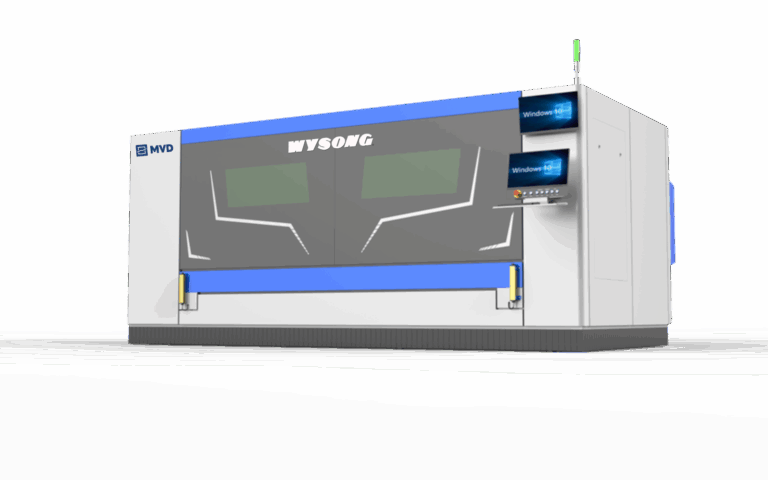

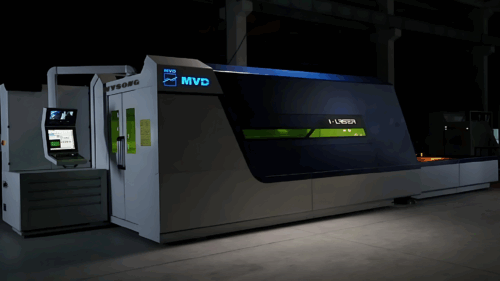

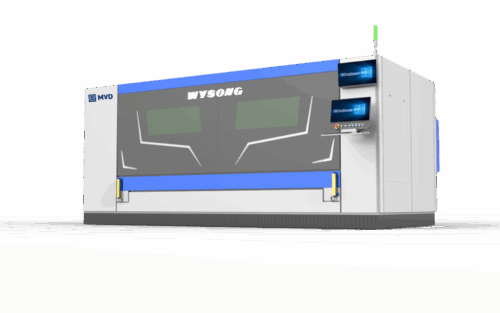

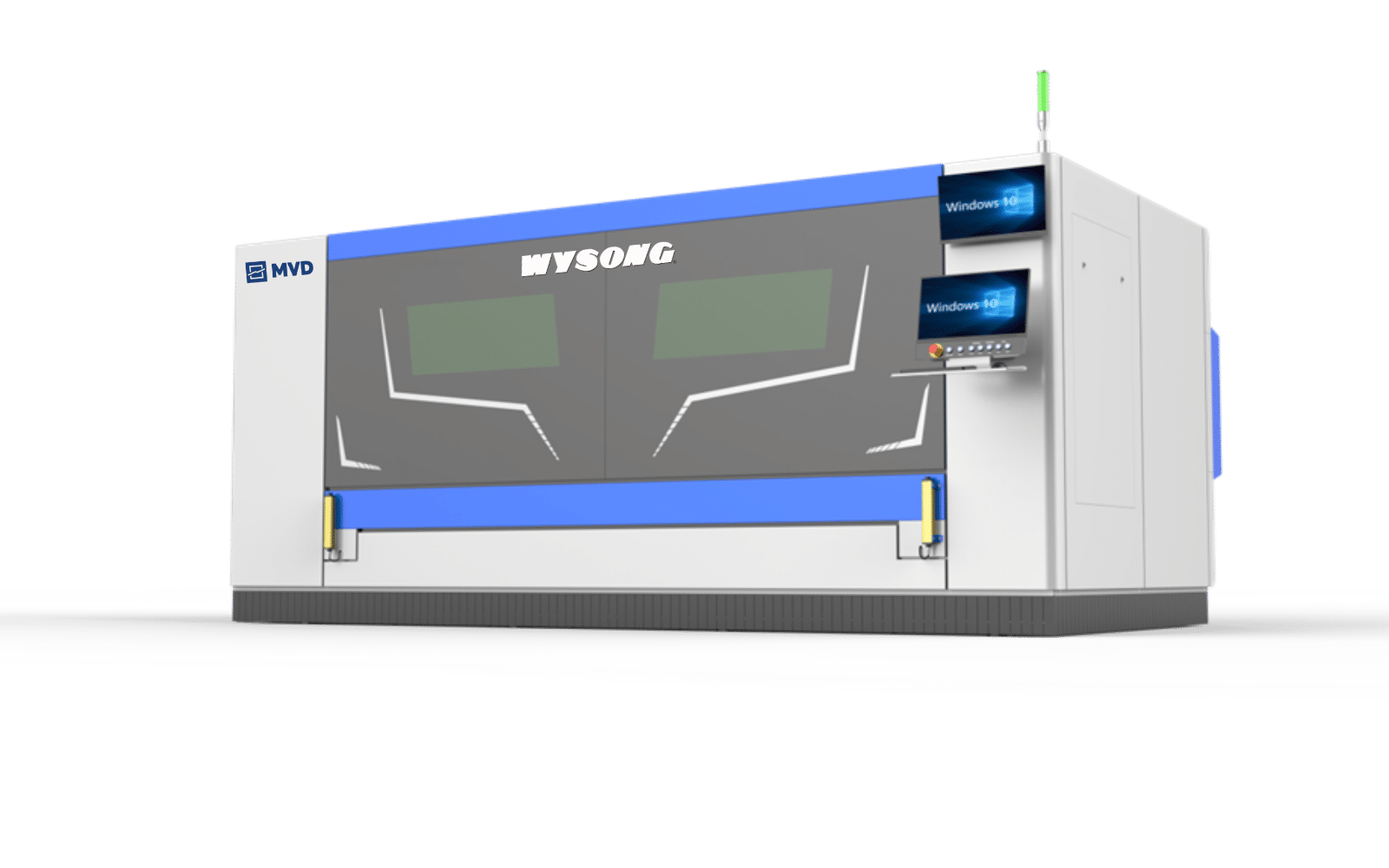

Wysong FM Series Fiber Laser

Compact Precision and Performance.

Discover the advantages of Wysong FM Series compact fiber lasers — designed to deliver accuracy, and efficiency for modern metal fabrication, with a small footprint.

Engineered with a focus on space savings for prototyping, job shops, and light duty production, the Wysong FM Series offers advanced laser solutions to take your capabilities to the next level.

About Us

QUALITY FIRST

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

FM Series

compact fiber laser

Enhanced Features for Modern Fabricators

Fully Enclosed Design: Our FM Series compact fiber laser features a fully enclosed structure with CE-certified protective glass. This design improves safety and efficiently captures and discharges smoke, ensuring cleaner and more environmentally friendly workspace.

Efficient Transportation: Shipped in one piece, our FM Series fiber laser reduces shipping costs and avoids damage from disassembly and reinstallation.

Equipment Specifications

Model: FM-1530

Laser Power: 1500W–6000W

Working Area: 5’ x 10’

Max Speed: 120 m/min

Max Acceleration: 1.5G

Positioning Accuracy: ±0.03 mm/m

Repeated Positioning Accuracy: ±0.03 mm

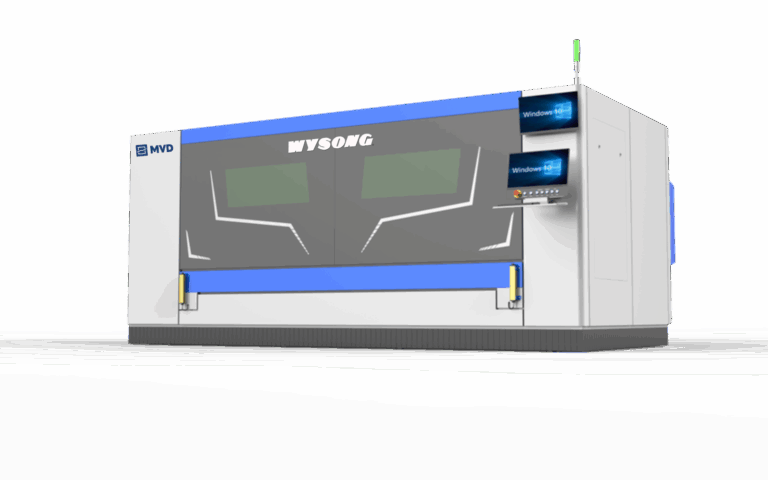

Controls

ESA VIS-875W Control

Windows operating system

Multi-touch graphic screen

Multifunctional keyboard, button/joystick/speed potentiometer

EtherCAT communications for data transfer or machine control

Enhanced Database for cutting parameters, for different type

materials and thicknesses

Fly Cut functions for same direction high-speed cutting

“No Piercing” technology for thin materials, efficiency time and

cost improvements

Better results at thick cuts, by prioritizing all piercings process before regular cutting

Remote connection to PC

Multi-language support

Enhanced sheet metal recognition software

Referencing and sheet alignment functions

Setting different user-login levels for operators/maintenance/admin

Multi-functional workpiece job order search/recall function

options

Power Ratings

Wysong FM Series fiber lasers are available in a wide range of power ratings, from 2 kW to 6 kW, each tailored to specific material types, thicknesses, and production goals. The power level of a fiber laser directly affects its cutting speed, thickness capacity, edge quality, and operational efficiency.

2 kW to 4 kW fiber lasers are well-suited for shops that focus on light-gauge materials such as mild steel, stainless steel, and aluminum up to around 1/4″ thick. These systems offer excellent cut quality and are highly efficient for thin-sheet processing, making them ideal for industries like HVAC, signage, and electrical enclosures.

6 kW fiber lasers provide a significant boost in cutting speed and material thickness capability. These mid-range systems strike a balance between versatility and power, cutting mild steel up to 1″, stainless steel up to 1/2″, and aluminum with excellent edge quality. They are often used in job shops and contract manufacturers where the range of material types and thicknesses varies daily.

Improve Your Workflow with the

FM Series Compact Fiber laser

Wysong fiber lasers deliver high-performance cutting across a wide range of materials and thicknesses. Our fiber lasers are engineered to give fabricators the speed and accuracy needed to stay competitive in today’s fast-paced manufacturing environment. Whether you’re processing thin-gauge stainless or thick mild steel, Wysong fiber lasers provide the edge quality and throughput modern shops demand.

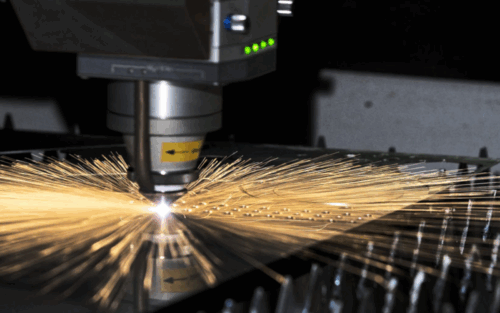

Why Cut with Fiber?

Cuts Faster – Delivers high-speed cutting on thin to thick materials with unmatched precision

Increases Shop Capacity – One machine can replace multiple slower-cutting systems, freeing up labor and floor space

Improves Edge Quality – Produces clean, burr-free cuts that often eliminate secondary processing.

Processes a Wide Range of Materials – Efficiently cuts mild steel, stainless steel, aluminum, copper, brass, and more.

Reduces Scrap – Precision cutting means fewer errors, tighter nesting, and better material utilization.

Ideal for High-Mix Production – Rapid changeovers and smart control software make it easy to handle varied part runs.

Ready to Upgrade Your Shop?

Let’s cut through complexity—together.

No matter your industry or production scale, Wysong fiber laser systems are built to help you cut smarter, faster, and cleaner. Get in touch with our experts today to explore the best solution for your operation.

- (800) 299-7664

"*" indicates required fields