Hydraulic Metal

Shears

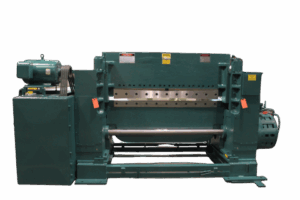

Wysong MC Series Hydraulic Metal Shears

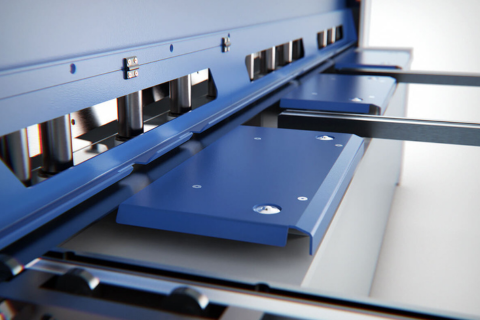

Our MC Series hydraulic metal shears are expertly designed for precise cutting tasks, catering to the needs of metal fabricating companies. Featuring advanced CNC technology, these machines function as efficient automatic shears, significantly streamlining operations and enhancing productivity. The MC Series CNC hydraulic shearing machines offer reliable performance, making them ideal for demanding projects that require both precision and efficiency. Built to withstand rigorous use, these shears ensure consistent, high-quality results, providing an invaluable asset to any fabrication environment seeking to optimize output and maintain excellence.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

OVERVIEW

Wysong MC Series Hydraulic Shears

Key Features:

Heavy-Duty Construction: Built with Wysong’s signature welded steel frame and hydraulic reliability for consistent performance in demanding environments.

Variable Rake Technology: Automatically adjusts the blade angle during the cut to match material type and thickness, reducing distortion and improving cut quality.

Increased Cutting Capacity: The variable rake design allows for greater cutting strength without increasing tonnage, enabling the machine to handle thicker or tougher materials.

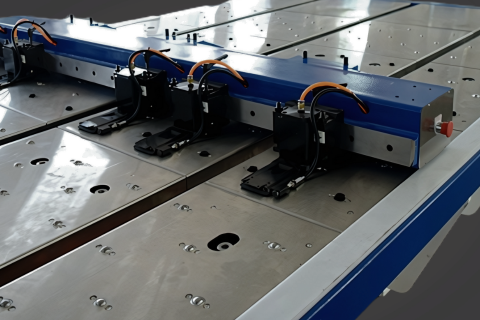

Fast, Accurate Backgauge: Servo driven cnc back gauge for precise positioning and repeatability in production.

CONTROLS

Cybelec 12G Touch Screen Control

Intuitive and user-friendly interface

Complete programming of parts in seconds

Quick machine setup with the EasyCut page

AutoCut function (continuous cut)

Sheet position offset, allowing to cut in the middle

Automatic calculations of the shear functions upon material specifications

Automatic blade gap

Automatic cutting angle

Automatic cutting length

Automatic back gauge foldaway

Management of sheet support integrated in machine cycle

options

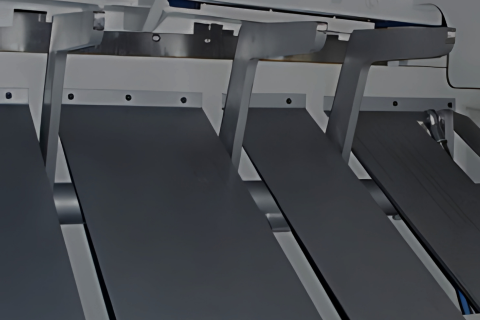

Sheet support

Designed specifically for Wysong shears, our sheet supports automatically catch and hold your material as it’s sheared, preventing sheets from dropping to the floor or shifting during processing.

By supporting the sheet from behind, this system eliminates the need for manual handling of large or awkward blanks, reducing operator fatigue and the risk of injury. Material stays flat and properly aligned during shearing, leading to tighter tolerances and higher-quality parts. It’s especially useful in high-throughput environments where consistency and repeatability are critical. Seamlessly integrates with your CNC control to deliver fully automated part cycles.

Available in a variety of sizes and configurations to match your specific shear model and application requirements, from short-run production to high-volume fabrication.

Sheet Feeder

Our CNC sheet feeder features a rugged frame, precision linear guides, and a high-performance servo drive system that ensures accurate and consistent feeding, even with large or heavy sheets. The system handles everything from light-gauge materials to thick plate with the same level of control and care, ensuring clean, accurate cuts every time.

Whether retrofitting to an existing shear or designing a fully automated cutting cell, Wysong CNC Sheet Feeders are built to enhance productivity, accuracy, and operator safety. Fabricators in industries ranging from HVAC and enclosure manufacturing to heavy plate processing rely on Wysong automation to stay competitive and efficient.

Improve Your Workflow with

Hydraulic Shears

Hydraulic shears, such as the Wysong MC Series, are built for reliability, flexibility, and precision. These machines use a hydraulic system to power the blade, offering greater tonnage and cutting capacity.

Applications Best Suited for Hydraulic Shears:

Thicker and Stronger Materials: Hydraulic shears are engineered to handle thicker plates and higher-strength materials like stainless steel and hardened alloys.

Adjustable Stroke Length: Operators can customize stroke lengths to improve cycle efficiency and reduce wear.

Low to Medium Production Runs: Their slower cycle times make them better suited for shops prioritizing versatility over speed.

ROI Considerations: Hydraulic shears have the ability to cut a wider range of materials, from light gauge to heavy-duty applications. The flexibility they offer can also open up new revenue streams, improving long-term ROI.

SUPPORTED with Pride

Every MC Series Hydraulic Shear is assembled with high-quality components and precision-machined parts for long-lasting performance with low operating costs.

Request More Info

Looking for a reliable hydraulic shear for your shop?

Wysong MC series hydraulic shears deliver unbeatable value, versatility, and trusted performance.

- (800) 299-7664

"*" indicates required fields