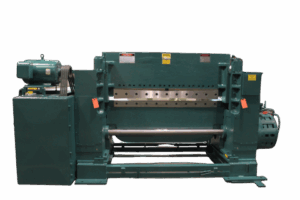

Heavy-Duty Shears

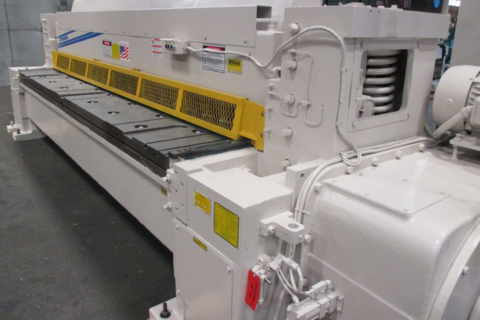

Wysong HD Mechanical Shears

Our heavy-duty mechanical shears are built for industrial metal cutting, offering unmatched strength and precision. Perfect for metal fabricating companies, these industrial metal shear machines ensure efficient processing of thick materials. As a trusted provider of industrial shears for metal, we deliver heavy-duty metal shearing machines that stand up to demanding tasks. Experience the reliability of our heavy-duty sheet metal shears for your toughest projects.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

OVERVIEW

Heavy Duty

Mechanical shears

Built to Last

Proven Mechanical Design: Time-tested flywheel and clutch system delivers consistent cutting power and reliability.

Instant Response: Mechanical drive allows for rapid cycle times and immediate shearing action when the pedal is pressed.

Robust Gear Drive: High-torque gear system transmits power efficiently and minimizes wear, even under heavy workloads.

Mechanical Hold-Down System: Secures the material firmly in place during the cut, reducing slippage and improving edge quality.

Ideal for Medium to High Volume Shops: Suited for repetitive jobs where speed, simplicity, and accuracy are critical.

American Engineered and Built: Manufactured in the USA with premium materials and strict quality standards.

options

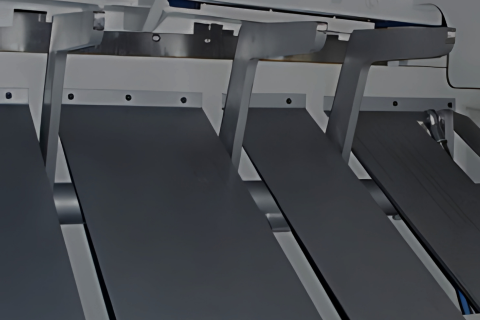

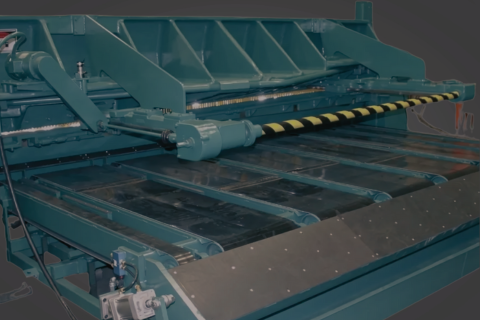

Sheet support

Designed specifically for Wysong shears, our sheet supports automatically catch and hold your material as it’s sheared, preventing sheets from dropping to the floor or shifting during processing.

By supporting the sheet from behind, this system eliminates the need for manual handling of large or awkward blanks, reducing operator fatigue and the risk of injury. Material stays flat and properly aligned during shearing, leading to tighter tolerances and higher-quality parts. It’s especially useful in high-throughput environments where consistency and repeatability are critical. Seamlessly integrates with your CNC control to deliver fully automated part cycles.

Available in a variety of sizes and configurations to match your specific shear model and application requirements, from short-run production to high-volume fabrication.

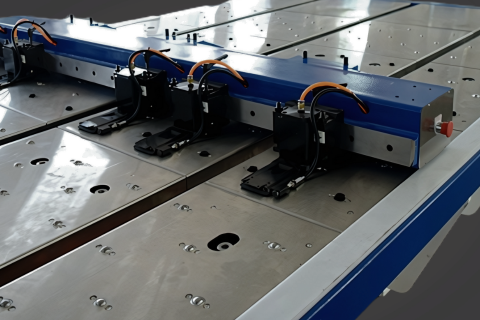

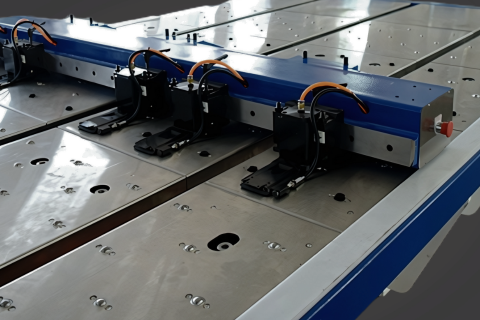

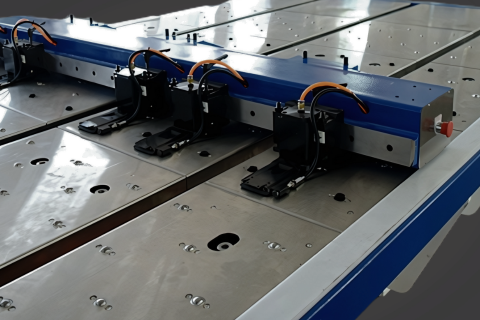

Sheet Feeder

Our CNC sheet feeder features a rugged frame, precision linear guides, and a high-performance servo drive system that ensures accurate and consistent feeding, even with large or heavy sheets. The system handles everything from light-gauge materials to thick plate with the same level of control and care, ensuring clean, accurate cuts every time.

Whether retrofitting to an existing shear or designing a fully automated cutting cell, Wysong CNC Sheet Feeders are built to enhance productivity, accuracy, and operator safety. Fabricators in industries ranging from HVAC and enclosure manufacturing to heavy plate processing rely on Wysong automation to stay competitive and efficient.

Sheet Feeder

Our CNC sheet feeder features a rugged frame, precision linear guides, and a high-performance servo drive system that ensures accurate and consistent feeding, even with large or heavy sheets. The system handles everything from light-gauge materials to thick plate with the same level of control and care, ensuring clean, accurate cuts every time.

Whether retrofitting to an existing shear or designing a fully automated cutting cell, Wysong CNC Sheet Feeders are built to enhance productivity, accuracy, and operator safety. Fabricators in industries ranging from HVAC and enclosure manufacturing to heavy plate processing rely on Wysong automation to stay competitive and efficient.

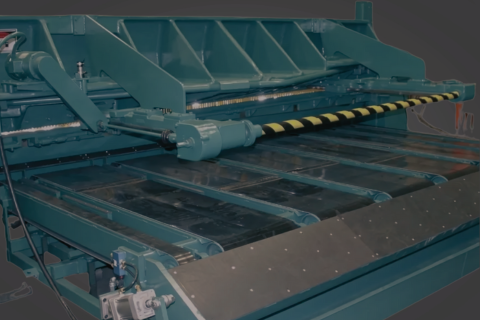

Conveyor // Stacker

Our conveyor/stacker systems move cut blanks away from the shear blade and organize them into neat, manageable stacks—eliminating the need for manual sorting or retrieval. This automation reduces downtime between cuts and keeps production flowing efficiently from start to finish.

At the heart of the system is a durable conveyor belt or roller track that catches each part as it drops from the shear and moves it down the line. Whether you’re cutting small blanks or full-width sheets, the conveyor stacker handles it all with industrial-grade reliability.

Wysong Shear Conveyor Stacker Units are ideal for high-volume environments where precision and efficiency matter most.

American Made. Built with Integrity.

With a brand heritage dating back over 100 years, Wysong machines are proudly designed and built in the USA. Our mechanical shears reflect our commitment to quality, simplicity, and service.

Improve Your Workflow with

Mechanical Shears

Mechanical shears, such as the Wysong HD Series, are built for speed, reliability, and precision. These machines use a flywheel-driven system to power the blade, enabling consistent and rapid cutting cycles.

Why Use Mechanical Shears?

Advantages of Mechanical Shears:

High-Volume Production: Mechanical shears excel in applications requiring repetitive, high-speed cuts. Their ability to maintain up to 60 strokes per minute (SPM) makes them ideal for industries like automotive, HVAC, and light manufacturing.

Thinner Materials: These machines perform exceptionally well with thinner sheet metals, where precision and speed are critical.

ROI Considerations: For fabricators focused on high-volume, low-to-moderate gauge materials, the speed of mechanical shears can result in significantly higher throughput than a comparible hydraulic shear.

Contact Us

Let’s cut through complexity—together.

No matter your industry or production scale, Wysong mechanical shears are built to help you process faster and more efficiently.

Get in touch with our experts today to explore the best solution for your operation.

"*" indicates required fields