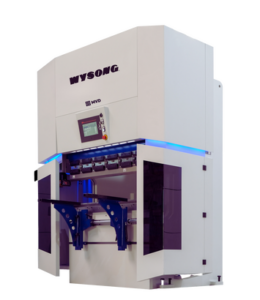

hybrid

press brakes

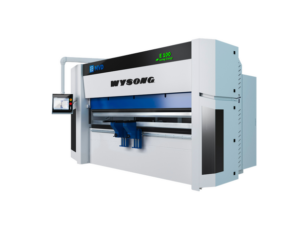

MH SERIES PRESS BRAKE

Built to last. Hybrid power for energy efficiency, speed, precision, and durability.

12″ Stroke, 16″ Throat Depth

Delem, ESA, or PC Controls

Servo Motorized Back Gauge

.0004″ Ram Repeatability

Sliding Front Sheet Support Arms

Front and Rear Operator Safety

Full Length Segmented Punch and 4 Way Die

LED illumination on RAM

Manual Pump for Machine Lubrication

About Us

QUALITY FIRST

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

BUILT TO LAST

CE CERTIFIED

110 - 550 TONS

UP TO 30' LENGTH

INDUSTRY 4.0

COMPATIBLE

OVERVIEW

MH SERIES Standard Features

Y1,Y2, X, R CNC (4 Axes)

12″ Stroke, 16″ Throat Depth

Servo Motorized Back Gauge with ±.001″ Accuracy (X=30″)

Manual Promecam Style Quick Clamp Punch Holder

Sliding Front Sheet Support Arms

AKAS Front Laser Safety

Rear Light Curtains

GIVI Optic Linear Scales (Italy)

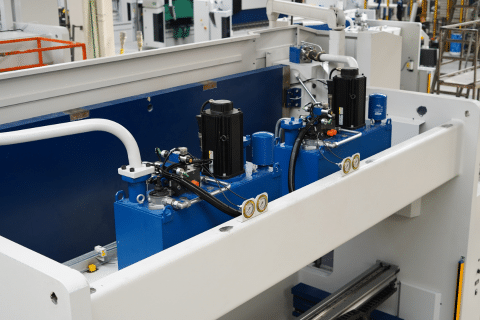

Bosch Sytronix Servo Hydraulic System

Full length, segmented 85° precision ground punches

Full length, segmented 4 way precision ground dies

LED illumination on RAM

Manual Pump for Machine Lubrication

Optional Features

Up to 6-Axis Back Gauge

2″ Extended Stroke

4″ Extended Throat

Delem, ESA, or PC Controls

Automatic Lubrication

Hydraulic Clamping

Wila Crowning

Wide Bottom Table

Manual or CNC crowning

CNC Sheet Followers

Additional Back Gauge Fingers

Hydraulic Oil Chiller, Heater

Electrical Cabinet A/C

Laser Bending Line

Extra Weight for Machine

CONTROLS

DA-69S

24″ high resolution color TFT

Support for industry 4.0 connectivity

USB, peripheral interfacing

Open system architecture (field service friendly)

Sensor bending & correction interface

Profile-S3D offline software (.dxf, .stp, .igs)

Remote diagnostics

DA-66S

24″ high resolution color TFT

Support for industry 4.0 connectivity

USB, peripheral interfacing

Open system architecture (field service friendly)

Sensor bending & correction interface

Profile-S2D offline software

Remote diagnostics

DA-58Tx

18,5″ high resolution color TFT

Bend sequence calculation

Crowning control

USB, peripheral interfacing

Open system architecture (field service friendly)

Profile-T offline software

Numerical touch screen programming

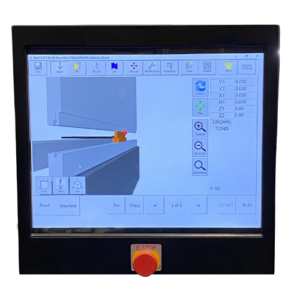

DA-53Tx

15″ high resolution color TFT

Crowning control

USB, peripheral interfacing

Open system architecture (field service friendly)

Profile-T offline software

DELEM

ESA

VIS-875W

21.5″ high resolution color TFT

Support for industry 4.0 connectivity

USB, peripheral interfacing

Open system architecture (field service friendly)

Sensor bending & correction interface

Remote diagnostics

VIS-860W

18.5″ high resolution color TFT

Support for industry 4.0 connectivity

USB, peripheral interfacing

Open system architecture (field service friendly)

Sensor bending & correction interface

Remote diagnostics

VIS-850W

15.6″ high resolution color TFT

Support for industry 4.0 connectivity

USB, peripheral interfacing

Open system architecture (field service friendly)

Sensor bending & correction interface

Remote diagnostics

VIS-640

15″ high resolution color TFT

USB, peripheral interfacing

Open system architecture (field service friendly)

Remote diagnostics

PC800 XD

19″ high resolution color touch screen

USB, peripheral interfacing

Open system architecture (field service friendly)

Auto program creation and 2D part simulation

.DXF tool and part import feature

Attach digital photos to part files to show tooling bend orientation

Bend Wizard offline software

Remote diagnostics

PC Controls

BACK GAUGES

Built to last and customizable for your application. Crafted from heavy duty, aircraft grade aluminum extrusion, our back gauges have been engineered to withstand the rigors of high volume production use while maintaining precision tolerances. With multiple configurations and optional additional THK rails for heavier plate applications, our press brake back gauges are among the best on the market today.

SINGLE AXIS (X)

Heavy Duty Back Gauge Rail

X=30″

TWO AXIS (X,R)

Heavy Duty Back Gauge Rail

X=30″, R=10″

FOUR AXIS (X,R,Z1,Z2)

Heavy Duty Back Gauge Rail

X=30″, R=10″, Z1, Z2

FIVE AXIS (X,R,Z1,Z2,X5)

Heavy Duty Back Gauge Rail

X=30″, R=10″, Z1, Z2, X5=+/-4″

SIX AXIS (X1,X2,R1,R2,Z1,Z2)

Heavy Duty Independent Axis Design

X1=30″, X2=30″,R1=10″, R2=10″,Z1, Z2

TOOLING

From precision ground punches and dies to cnc hydraulic clamping and crowning systems, we’ve got you covered.

TOOLING

All Wysong press brakes come with a full length set of precision ground, segmented upper and lower tooling.

Wysong partners with all major suppliers to provide tooling packages for our customers, including Rolleri, Wila, Wilson Tool, Eurostamp, and Mate, among others.

MANUAL QUICK CLAMPS (STANDARD)

Our press brakes come standard with manual, Promecam style quick clamps with an adapter plate to accommodate North American or European style punches.

Alternative style quick clamps are also available upon request.

UPPER HYDRAULIC CLAMPING

We offer Wila upper hydraulic clamping on our press brakes, available for punches with Wila/New Standard, European, and American tangs.

Wila Pro: Rated for pressures up to 180 tons/meter

Wila Premium: Rated for pressures up to 250 tons/meter

LOWER HYDRAULIC CLAMPING

Lower hydraulic clamping is also available for your press brake.

Wila Pro: Rated for pressures up to 180 tons/meter

Wila Premium: Rated for pressures up to 250 tons/meter

WILA CROWNING

For press brakes over 7 feet in length, we offer crowning units with genuine Wila wedges as standard. We can offer two types of crowning units, manual and cnc, with standard and heavy duty motors for high tonnage applications.

All Wysong stock press brakes come with Wila CNC crowning as a standard option.

WIDE BOTTOM TABLE

Wysong offers custom width bottom tables for higher tonnage applications, ranging from our standard 6″ wide bottom table with North American die slot up to 30″.

Our engineering team is available to evaluate your parts and present a custom bottom table and machine configuration for your specific needs.

SAFETY SYSTEMS

We’re dedicated to helping you protect your most valuable asset, your people. Wysong press brakes come standard with best in class German laser safety systems from Fiessler and light curtains at the rear of the machine. To date more than 35,000 AKAS laser safety systems have been sold worldwide as customers demand the Fiessler brand, known for both performance and reliability. Additional point of operation safety and guarding options available upon request.

FIESSLER AKAS II

CE and UL Certified, OSHA Approved

Rapid Approach up to 3/8″ Above Part

FIESSLER AKAS V

CE and UL Certified, OSHA Approved

Rapid Approach up to Part

REAR MACHINE SAFETY

CE Certified Standard Rear Light Curtains Require Resetting Machine if Someone Enters the Restricted Area Near the Back Gauge. Metal Doors Also Available Upon Request.

REQUEST A PROPOSAL

Contact Us

We take great pride in our equipment and customer relationships. With over 20,000 machines still in production today, Wysong is a leader in the machine tool industry in North America.

Want to learn more about our equipment lines? Contact us today.

"*" indicates required fields