shears

Wysong Shears

When accuracy, reliability, and rugged performance matter, Wysong Shears deliver. Our shears are engineered for high-volume sheet metal processing with clean, burr-free cuts every time.

From job shops to major production lines, Wysong mechanical and hydraulic shears are trusted across the United States by fabricators who refuse to compromise.

About Us

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Machines Backed By People

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

We understand that every shop is different, which is why we take the time to learn your processes, challenges, and goals before recommending solutions.

Whether you need complementary phone support, field service, technical training, or new equipment for your shop, we’re here to help.

Which Type of Shear is Best for my Application?

Mechanical Shears

Precision and Speed for High-Volume Work.

Precision and Speed for High-Volume Work.

Mechanical shears, such as the Wysong HD Series, are built for speed, reliability, and precision. These machines use a flywheel-driven system to power the blade, enabling consistent and rapid cutting cycles.

Advantages of Mechanical Shears:

High-Volume Production: Mechanical shears excel in applications requiring repetitive, high-speed cuts. Their ability to maintain up to 60 strokes per minute (SPM) makes them ideal for industries like automotive, HVAC, and light manufacturing.

Thinner Materials: These machines perform exceptionally well with thinner sheet metals, where precision and speed are critical.

ROI Considerations: For fabricators focused on high-volume, low-to-moderate gauge materials, the speed of mechanical shears can result in significantly higher throughput than a comparible hydraulic shear.

Wysong Mechanical Shears

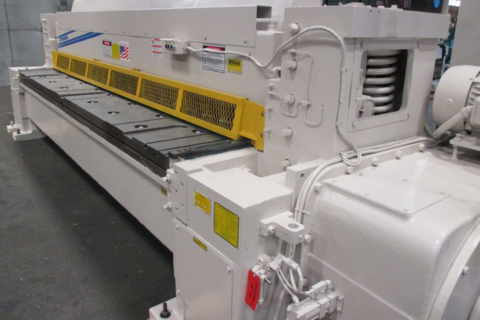

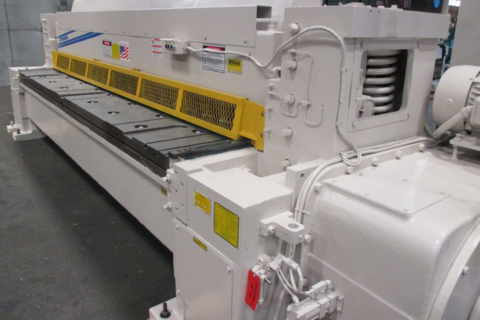

Hydraulic Shears

Power and Versatility for Heavy-Duty Jobs.

Power and Versatility for Heavy-Duty Jobs.

Hydraulic shears rely on hydraulic cylinders to power the blade, offering greater tonnage and cutting capacity. They are the go-to choice for heavy-duty applications and thicker materials.

Applications Best Suited for Hydraulic Shears:

Thicker and Stronger Materials: Hydraulic shears are engineered to handle thicker plates and higher-strength materials like stainless steel and hardened alloys.

Adjustable Stroke Length: Operators can customize stroke lengths to improve cycle efficiency and reduce wear.

Low to Medium Production Runs: Their slower cycle times make them better suited for shops prioritizing versatility over speed.

ROI Considerations: Hydraulic shears have the ability to cut a wider range of materials, from light gauge to heavy-duty applications. The flexibility they offer can also open up new revenue streams, improving long-term ROI.

Wysong Hydraulic Shears

Considering a new shear?

- (800) 299-7664

"*" indicates required fields