Beveling

Beveling Made Simple

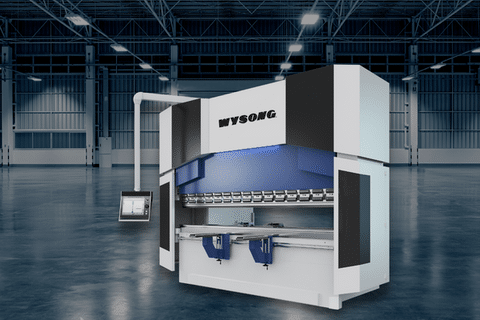

Beveling is a key step in metal fabrication that prepares parts for welding, improves edge quality, and enhances fit-up for assembly. Whether you’re working with plates, pipes, or structural components, a clean, consistent bevel ensures stronger welds and reduces the need for post-weld grinding. Wysong’s beveling machines make this process fast, accurate, and repeatable—every time.

Why Wysong?

Quality First

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

WE CARE ABOUT YOU

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

Whether you need field service, technical training, or complementary phone support, we’re here to help.

OVERVIEW

Improve Your Workflow with Automated Beveling Machines

Whether you’re beveling for MIG, TIG, or submerged arc welding, Wysong beveling machines by Tfon offer precise angle control, adjustable speed, and clean cuts with minimal heat-affected zones. Our line includes plate bevelers, pipe bevelers, and edge milling machines, with both manual and automatic models available to suit different shop sizes and applications.

These machines are ideal for preparing carbon steel, stainless steel, and aluminum parts for welding—quickly and safely.

options

Strokes per Minute (SPM)

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Drivetrain

When you partner with Wysong, you get more than just a great machine. Our team has hundreds of years of combined experience with fabrication equipment, and we use this experience daily to help our customers.

Whether you need field service, technical training, or complementary phone support, we’re here to help.

Strokes per Minute (SPM)

Wysong equipment is well known throughout North America for being among the most durable machines on the market. Whether your machine is produced at our 110,000 sf factory in North Carolina or by one of our carefully selected partners, we promise to provide proven fabrication equipment with a focus on quality and customer service.

We spend an average of 40 hours of quality assurance on every machine we ship to ensure that it meets our demanding standards.

Why Use Beveling Machines?

Here are the main benefits:

Weld-Ready Edges: Clean, uniform bevels improve penetration and weld quality while reducing filler use.

Reduced Labor: Beveling by hand is slow, inconsistent, and tiring. Machines finish the job in a fraction of the time.

Improved Safety: Automating beveling removes the risks of grinders, torches, and hand tools.

Better Fit-Up: Precision bevels ensure easier, more accurate assembly and less rework.

Material Flexibility: Adjustable angle settings and feed rates handle a wide range of thicknesses and materials.

Ongoing Support and Easy Maintenance

We make it easy to keep your beveling equipment up and running. Wysong stocks parts here in the U.S., with most orders shipped the same day. We also provide setup guidance, preventive maintenance tips, and troubleshooting support by phone or in the field—so you’re never left on your own.

Choose Wysong for Reliable, High-Performance Beveling Equipment

With Wysong beveling machines by Tfon, you get the reliability of European engineering and the support of an American brand that’s been trusted for over 140 years. These machines are designed to streamline your welding prep, increase your productivity, and deliver repeatable, professional results across every job.

- (800) 299-7664

"*" indicates required fields